Please note that this information is the latest available from our various material suppliers and is subject to change without notice.

1) Granite, Marble & Reconstituted stone

Natural stone & Caesarstone, Silestone, Smartstone Quantum Quartz etc

(nominal 20mm slabs with 20mm edge or mitred/laminated apron/edge profile):

- </= 150mm overhang with no support in 20mm material is permitted to allow a 20mm finished edge; for overhangs over 150mm, substrates are required

- Extra support rails on edges adjacent to underbench ovens, sinks and dishwashers required.

- Up to 300mm overhang without additional support (18mm substrates sufficient) at </= 600mm spacing.

- Over 300mm overhang, brackets, legs or metal frame required to support substrates

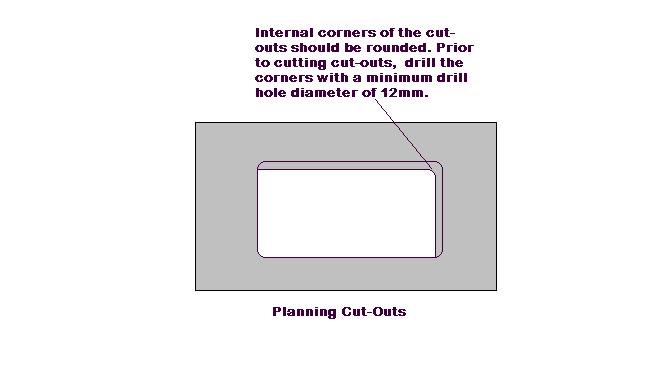

- A minimum of 80mm is required between the front of the bench top edge and cut outs such as sinks or hotplates. A minimum of 50mm is required from the rear of the bench top to cut outs. A minimum of 35mm is required between sink and tap cut outs.

2) Porcelain 12mm panels

DEKTON, INFINITY, LAMINAM , NEOLITH & QUANTUM SIX+ 12mm

- 12mm panels require full 18mm substrates. 40mm mitred edges require 26mm substrates.

- </= 150mm overhang with no support is permitted in 12mm material to allow a finished 12mm edge; for overhangs over 150mm, substrates are required.

- For 40mm mitred edges, substrates will need to be 8mm thicker than usual, ie: 26mm substrates in lieu of 18mm.

A minimum distance of 50mm must be kept from each cut out; ie: from edge to cut out and between cut outs. - Under mount sink cut outs should be the same size as the sink or rebated – ie: material not overhanging.

- Drainage Grooves, Drainage Sections and Flush Mounting for appliances are not possible.

3) Porcelain 5, 6 or 8mm panels

- ONLY TO BE USED FOR SPLASHBACKS or other vertical surfaces.

- Not suitable for bench top applications.

4) Porcelain 20mm panels

- 20mm panels do not require substrates; however, back to front supports must be fabricated every 600mm and installed along the perimeter of cut outs larger than 600mm.

- Standard overhang for 20mm is 300mm. Additional support in the form of MDF substrates (or similar) will be required for overhangs greater than 300mm.

- A minimum distance of 50mm must be kept from each cutout; ie: from edge to cut out and between cut outs.

- Under mount sink cut outs should not overhang sinks – rebated or level with the sink is preferred.

- Drainage Grooves and Drainage Sections are possible but must be kept to a minimum of 25% of the material; ie: maximum 5mm in 20 mm material.

- Flush mounting of Hot Plates is possible, but it should be noted that the cut out will have rounded corners – not square as per the outline of most appliances.

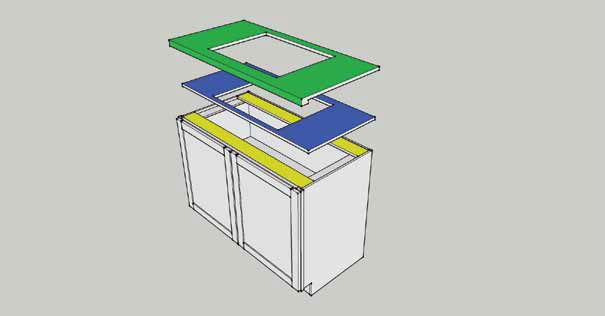

Stone bench tops cannot be installed straight onto open carcasses. For benches with edges deeper than the standard 20mm thickness, substrates (which are normally made of 18mm MDF) must be affixed to the top of all cabinet carcasses to support the weight of the stone bench top (refer to diagram below), and must be level to keep the stone flat. The substrate must be offset 25 mm (for mitred edges) or 45 mm (for laminated edges) from the desired finished edge on each exposed side of the stone.

The substrate should be installed using small “L-brackets” screwed into the cabinet carcass from beneath the substrate. This is so, if the stone needs to be moved or replaced, the stone and substrates can be removed without damaging the carcass.

The substrate must have all cut-outs (sink, cook top, tap hole, waste hole, etc.) cut from it prior to installation of stone.

Under mount sinks are be recessed into the substrate, allowing for 5mm movement in all directions.

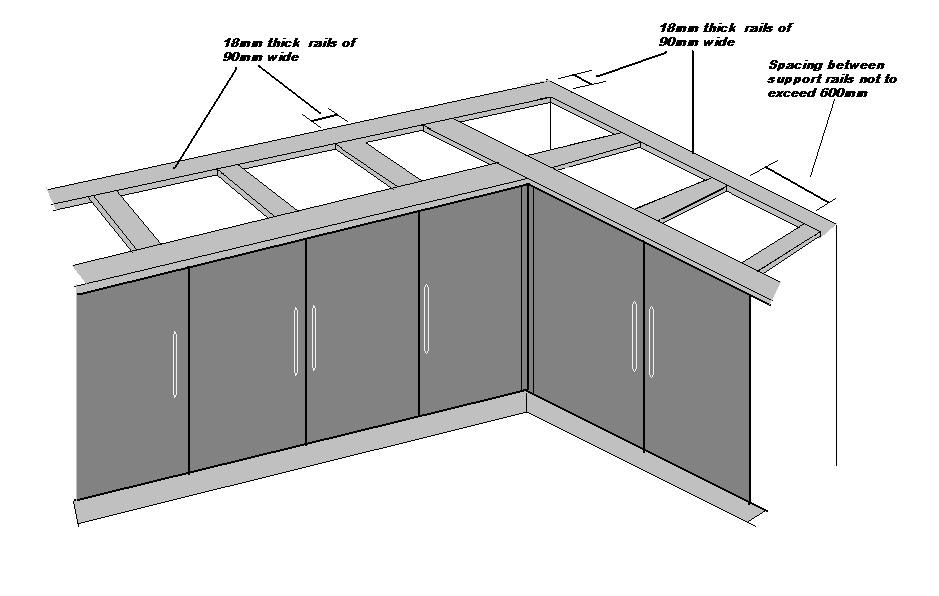

A rail on edge to front and back of hot plates, sinks and dishwashers must be installed (refer to diagram below).

For 20mm edge benches, a top on each cabinet carcass, with particular attention to rails, is required, as indicated in the following diagram. A maximum span of 600mm is allowed. Alternatively, a substrate can be used and finished in the same material as your cabinetry to create a shadow line effect. Please discuss support options with your cabinetmaker (and/or refer to INFORMATION SHEET B). An overhang of up to 150mm can be achieved without a substrate support.

Templates and substrates will usually be provided by your cabinetmaker. In the case of flat-pack style cabinets and revamps you may need to arrange for the supply of these items separately. It is advisable to have these produced professionally as our quote allows for one site visit for template check measure and/or collection, and one installation visit. Additional charges will be levied for additional check visits or on-site amendments to bench tops.Please note that benches cannot be installed snug with adjoining walls/panels as stone is subject to expansion and contraction and therefore needs to have a suitable gap. This is also applicable to benches which adjoin free standing ovens.

Templates

Templates are a pattern of the desired bench top(s) and are to be provided to Multiform Stone by the customer. These will normally be constructed of 3 – 4mm thick MDF timber and are to be the exact size and shape of the finished stone product. Any appliance, sink and tap / water filter tap hole locations and sizes must also be indicated and cut out on the template and substrate. All dimensions should be clearly written on the front face. The client name, install address, product (brand and stone name) and edge style should also be clearly noted, as should indications of which edges are to be polished (these should be marked with a “ // “ for 20mm edges or “ X “ for 40mm edges, a “ ⮿ “ for other edge depths and a “ O “ for waterfalls).

Base cabinets must be complete, in place and structurally sound before templates are constructed to ensure an accurate fit, particularly where the bench is to adjoin a wall or fixed panel.

Once templates have been constructed, we can process your order and you will be advised of an anticipated delivery/installation date. A Multiform Stone team member will call to arrange an appointment to “laser check measure” your templates onsite and may take them and any under mount sinks/basins to our factory (this will be determined by our template measurer at this appointment).

For benches with under mount sinks we will require the cut out to be precise and for details including sink model number, brand, and relevant mounting instructions such as “cut out edge flush with sink” or “exposed lip of 10mm”, to be clearly written on the relevant template. The customer will also need to provide the sink and any accessories (such as drainage bowls, cutting boards, etc.) at the time of check measure.

At this stage, a deposit of 50% of the quotation price will be required.

Delivery and/or installation by Multiform Stone personnel will occur approximately two to two and a half weeks after template ready notification and deposit payment. Please note that there are specific times of the year, such as pre-Christmas, when a longer time frame can be anticipated.

Final payment is required prior to installation. Please enquire about payment methods when your installation is arranged.

Some customers like to retain their cut outs (created for sinks, hotplates, etc.) for future use. Please note that cut outs will have rough edges. If you would like to have your cut outs edged and polished so that you can use them, please specify your requirements, including dimensions, at the time of ordering and ensure that these details are recorded on your templates. Our estimators will provide you with a price for this option which can be included on your initial quote or added prior to or at template measure.

The resin or glue that has been used to bond your stone bench top to your substrate needs at least 24 hours to harden or go off. It is preferable to book your plumber in for two days after your bench has been installed to ensure that this process has occurred and to avoid any movement that may impact on the structural integrity of your bench. This also applies to inset cook tops. Likewise, it is recommended that splashbacks be installed a minimum of two days after your stone is installed.

Please ensure that any tradesmen that visit after your stone is installed are advised that they cannot sit or stand on the benches and the stone should be protected while tradesmen are working in the vicinity. Please continue to respect your benches by not standing or sitting on them at any time.

You will need to register your warranty with the company that manufactured your stone, generally within 30 days of installation:

| Caesarstone | www.caesarstone.com.au |

| Quantum Quartz | www.quantumquartz.com.au |

| Smartstone | www.smartstone.com.au |

| Silestone / DEKTON | www.cosentino.com (Company Name: Multiform, ID: 6000021900) |

| EssaStone | www.essastone.com |